The following Cut Score Application details correlate ANSI cut scores to their relevant applications.

-

200 – 499 GRAMS: TYPICAL USES

Light to Medium-duty Assembly, Maintenance & Repair, Material Handling and Warehouse Shipping and Receiving.

-

500 – 999 GRAMS: TYPICAL USES

Light to Medium-duty Assembly, Automotive, Construction, Maintenance & Repair, Material Handling and Metal Handling.

-

1,000 – 1,499 GRAMS: TYPICAL USES

Medium to Heavy-duty Assembly, Automotive, Construction, Maintenance & Repair, Material Handling and Metal Handling.

-

1,500 – 2,199 GRAMS: TYPICAL USES

Medium-duty Assembly, Automotive, Construction, Glass Fixture Installation, Material Handling and Metal Handling.

-

2,200 – 2,999 GRAMS: TYPICAL USES

Heavy-duty Assembly, Automotive, Construction, Glass Handling, Material Handling, Metal Handling and Metal Stamping.

-

3,000 – 3,999 GRAMS: TYPICAL USES

Heavy-duty Assembly, Automotive, Construction, Glass Handling, Material Handling, Metal Handling and Metal Stamping.

-

4,000 – 4,999 GRAMS: TYPICAL USES

Heavy-duty Assembly, Automotive, Construction, Glass Manufacturing, Metal Handling and Metal Stamping.

-

5,000 – 5,999 GRAMS: TYPICAL USES

Heavy-duty Assembly, Automotive, Construction, Glass Manufacturing, Metal Handling and Metal Stamping.

-

6,000+ GRAMS: TYPICAL USES

Heavy-duty Assembly, Automotive, Construction, Glass Manufacturing, Metal Handling and Metal Stamping.

Hi Performance GloveG-Tek® PolyKor®16-MPT630

Hi Performance GloveG-Tek® PolyKor®16-MPT630

Extended Use Disposable GlovesGrippaz™ Skins67-246

Extended Use Disposable GlovesGrippaz™ Skins67-246

Hi Performance GloveG-Tek®120-5150

Hi Performance GloveG-Tek®120-5150

Evaporative CoolingEZ-Cool® Max396-EZ900

Evaporative CoolingEZ-Cool® Max396-EZ900

Cut Resistant GlovesG-Tek® PolyKor®16-560

Cut Resistant GlovesG-Tek® PolyKor®16-560

Cut Resistant GlovesG-Tek® Paradox™16-541

Cut Resistant GlovesG-Tek® Paradox™16-541

Protection From ColdG-Tek® PolyKor®41-1417

Protection From ColdG-Tek® PolyKor®41-1417

Heated ApparelBoss®300-HV100

Heated ApparelBoss®300-HV100

General Purpose Gloves - CoatedG-Tek®34-315

General Purpose Gloves - CoatedG-Tek®34-315

Protection From ColdG-Tek® PolyKor®41-1415

Protection From ColdG-Tek® PolyKor®41-1415

Cut Resistant GlovesG-Tek® Paradox™16-351

Cut Resistant GlovesG-Tek® Paradox™16-351

Hi Performance GloveG-Tek® PolyKor® X7™16-MP585

Hi Performance GloveG-Tek® PolyKor® X7™16-MP585

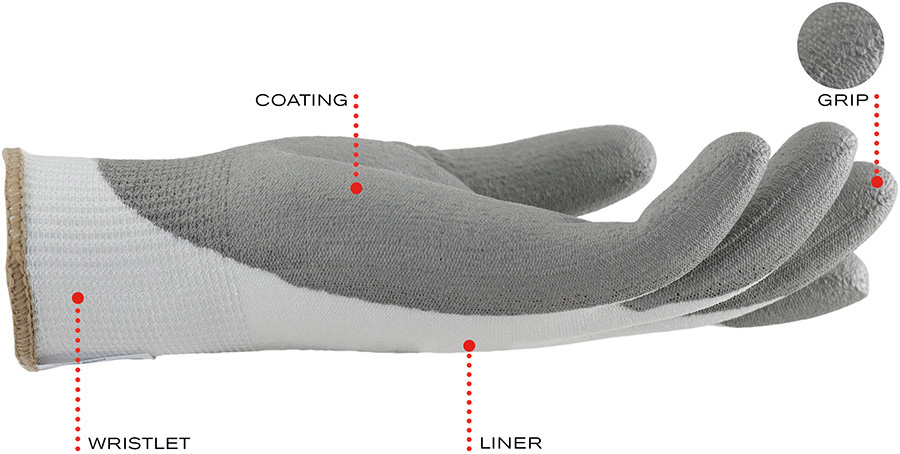

COATED SEAMLESS KNIT

COATED SEAMLESS KNIT  POLYMER

POLYMER  CUT AND SEWN

CUT AND SEWN